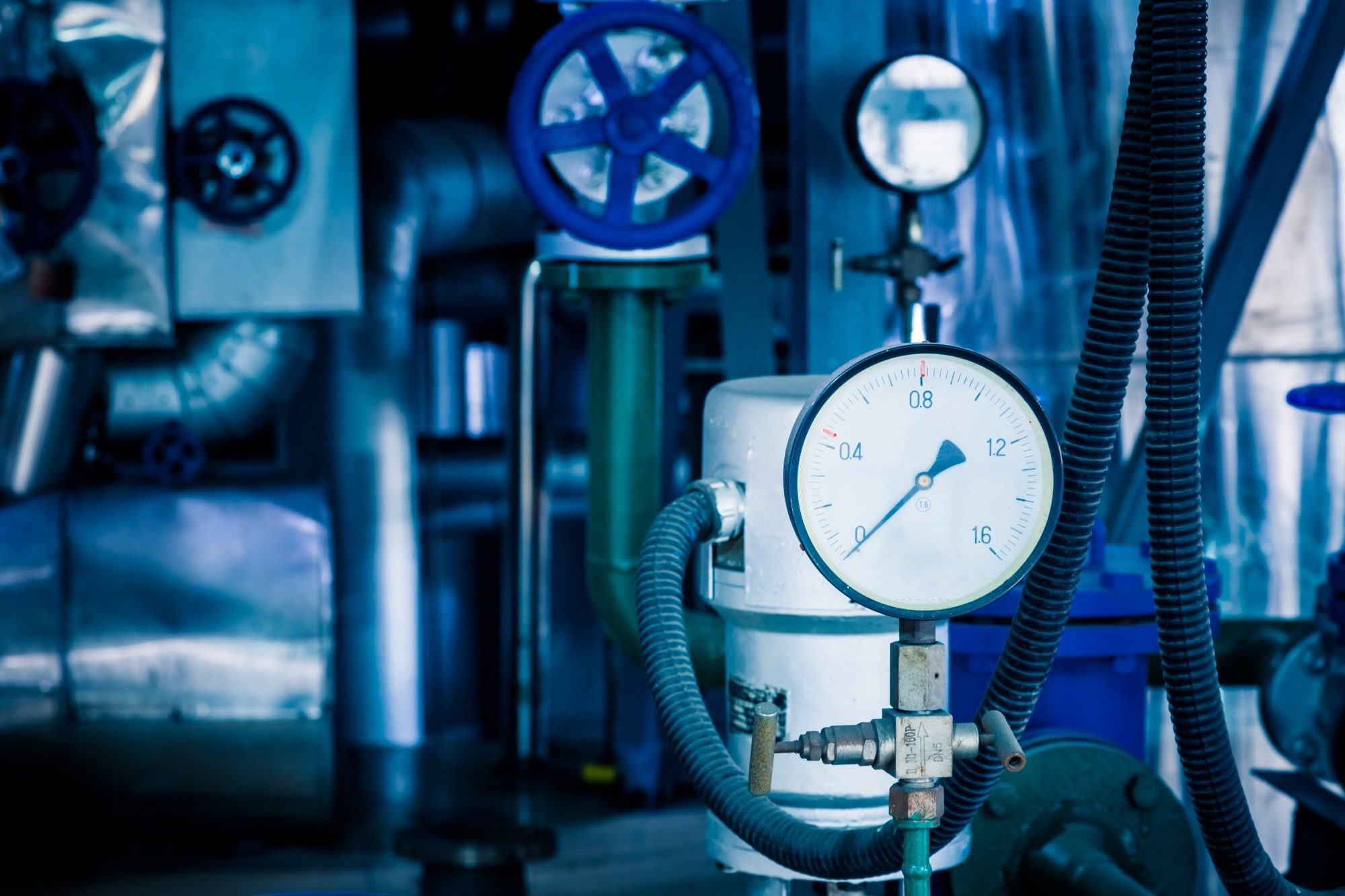

SSOV Control Panel

SSOV Control Panel

- Picture:

- Checkbox: Yes

- Feature Title: Using a microfilter capable of filtering particles larger than 5 microns

- Feature Description: Particles larger than 5 microns typically include rust particles, sand, grit, and some microorganisms. Removing these particles from the fluid prevents damage to equipment and extends its lifespan.

- Feature Title: Using a specialized regulator for operation at working pressures of 150, 300, and 600

- Feature Description: A regulator is a device used to reduce and control the pressure of fluids (such as gas, air, or liquids). In many industrial systems, precise pressure control is necessary to prevent equipment damage and ensure proper system operation. Regulators designed for working pressures of 150, 300, and 600 PSI are ideal for high-pressure industrial applications.

- Feature Title: A dedicated tripping system that allows for pressure setting at both low and high limits.

- Feature Description: A tripping system, also known as an automatic shutdown system, is designed to automatically deactivate equipment in the event of abnormal or dangerous conditions. This specialized system, with its dual pressure setting capability, allows you to define two distinct pressure levels for automatic system shutdown. This means you can set both a low and high pressure threshold.

- Feature Title: Using a pneumatic valve with a manual reset capability.

- Feature Description: A pneumatically operated valve with a manual reset function is a directional control valve that, once activated, can only be reset and prepared for the next operation by a manual actuator. These valves are commonly used in systems that require an additional safety mechanism, where manual confirmation is necessary after each operation to ensure the system is ready for the next cycle.

- Feature Title: Equipped with a fail-safe mechanism

- Feature Description: The primary reason for using a fail-safe mechanism in safety shutoff valves is to enhance system safety. In the event of a fault or power failure, the valve automatically closes, preventing fluid leakage and potential accidents.

- Feature Title: Manual operation capability

- Feature Description: The manual operation capability in a safety shutoff valve control panel means that, in addition to automatic activation or deactivation based on predefined parameters (such as pressure, temperature, and fluid level), the operator can manually control the safety valve.

- Feature Title: Ability to connect to a tank for operation without a panel input

- Feature Description: The panel can utilize level sensors to monitor the fluid level in the tank and activate or deactivate the valve as needed. It can also measure the internal pressure of the tank and activate the valve if the pressure exceeds a predetermined limit, preventing system damage.

- Picture:

- Checkbox: Yes

- Picture:

- Checkbox: Yes

- Designed and manufactured for operating pressures of classes 150, 300, and 600

- temperature range of -29 to +60 degrees Celsius.

- Picture:

- Checkbox: Yes

- Usage Title: Used as a control panel for ball valves in gas pressure reduction stations.

- Usage Description: Ball valve control panels play a crucial role in gas pressure reduction stations. These panels serve as the 'brain' of the system, responsible for precise and safe control of gas flow.

- Usage Image:

SSOV Control Panel

Relying on its technical strength and experience, Daniyal Para Development Company has the possibility to produce according to your request.

Designed for use in natural gas service

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Designed for use in natural gas service

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Designed for use in natural gas service

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Designed for use in natural gas service

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Technical Specifications

Design and production in pressure classes 150, 300 and 600

Design and production in pressure classes 150, 300 and 600

Design and production in pressure classes 150, 300 and 600

Design and production in pressure classes 150, 300 and 600

Gas pressure reduction stations

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Gas pressure reduction stations

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Gas pressure reduction stations

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Gas pressure reduction stations

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.