Linear Actuators with Handwheel

Linear Actuators with Handwheel

- Picture:

- Checkbox: Yes

- Feature Title: Simple connection capability on the relevant equipment

- Feature Description: The linear actuator is designed to be easily connected to various equipment without the need for complex tools or advanced technical knowledge. This feature significantly simplifies the installation and setup process of the actuator, reducing installation time and costs.

- Feature Title: Capability to install a HANDWHEEL locking system to prevent accidental movement

- Feature Description: The ability to incorporate a Handwheel locking system is a critical safety feature in linear actuators, especially in high-risk industrial environments. This feature prevents accidental actuator movement and potential incidents by adding a locking mechanism to the Handwheel.

- Feature Title: Minimizing system slippage through the use of bearings

- Feature Description: Bearings play a crucial role in reducing friction and increasing the lifespan of equipment. In linear actuators, the use of bearings ensures smooth linear motion with minimal friction and slippage. This is particularly important in applications where positioning accuracy and speed are critical.

- Picture:

- Checkbox: Yes

Warning: foreach() argument must be of type array|object, string given in /home/danielco/domains/danielco.ir/public_html/wp-content/plugins/meta-box-aio/vendor/meta-box/meta-box-group/group-field.php on line 453

- Manufacture of pneumatic power up to 1300 KN

- Capable of operating in temperatures ranging from -30°C to +80°C

- Designed for temperatures ranging from -50°C to +150°C

- Manual control via handwheel

- Picture:

- Checkbox: Yes

- Usage Title: Steel industries

- Usage Description: As a powerful tool in many industries, including the steel industry, this linear actuator plays a significant role. In steel mills, these devices are used for a wide range of operations, such as controlling valves, moving components, and automating processes.

- Usage Image:

- Usage Title: Use as an actuator in Globe valves

- Usage Description: By adjusting the input air pressure to the actuator, the opening and closing of the ball valve can be controlled with high precision. This is especially important in processes that require precise fluid flow control.

- Usage Image:

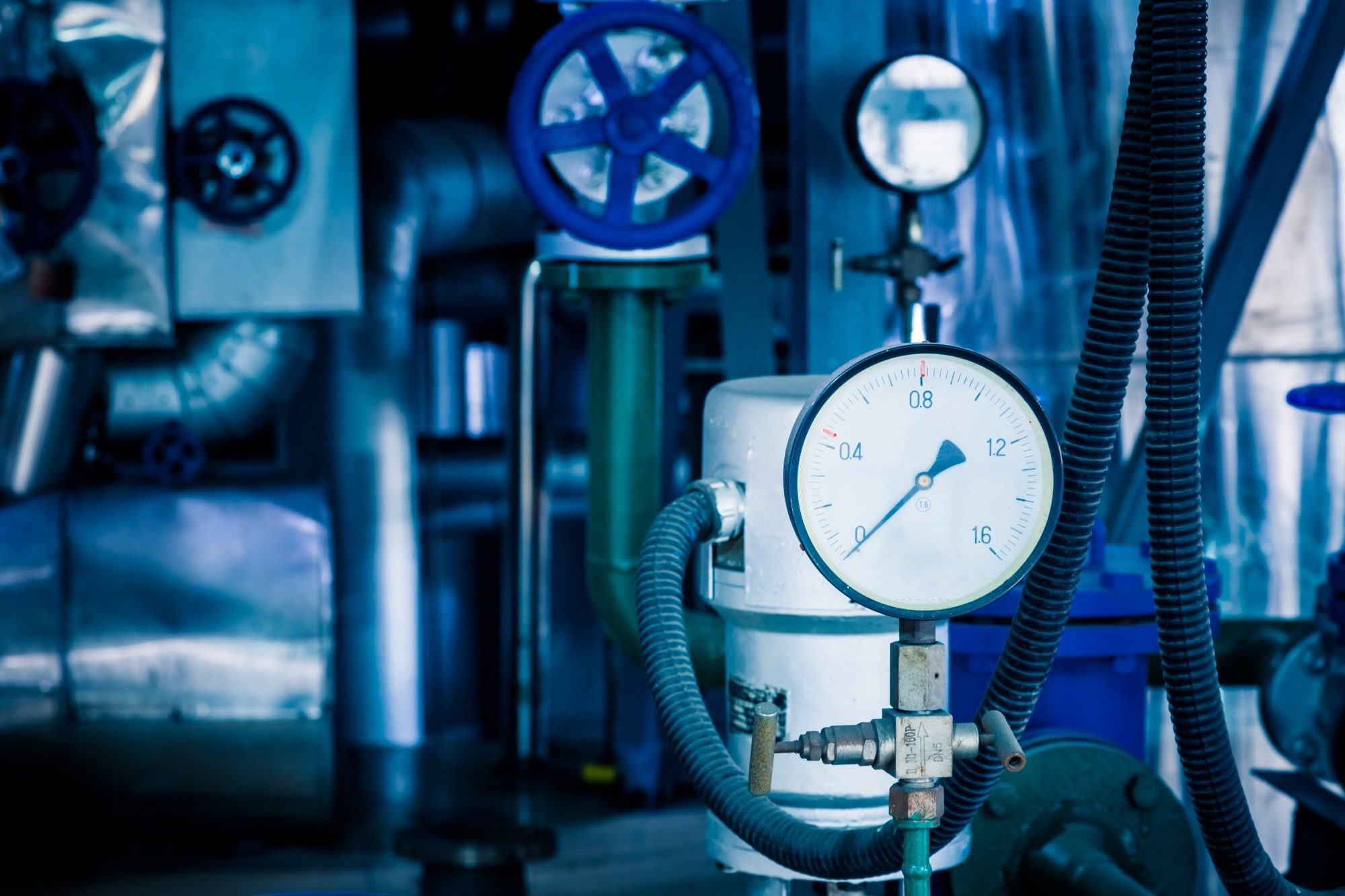

- Usage Title: Use in control valves

- Usage Description: Control valves are used to precisely regulate the flow of fluids in pipelines. This device acts as an actuator for these valves, adjusting their position to control the degree of valve opening.

- Usage Image:

- Usage Title: Use in STARTUP ejectors

- Usage Description: Linear actuators, capable of converting electrical, pneumatic, or hydraulic energy into linear motion, play a crucial role in the operation of startup ejectors. These ejectors are devices that use a high-pressure fluid (usually steam or air) to propel another fluid at a lower pressure.

- Usage Image:

- Usage Title: oil and gas and petrochemical industries

- Usage Description: These devices are widely used in various industries, particularly those requiring precise and powerful linear motion control. In the oil, gas, and petrochemical industries, linear pneumatics play a crucial role.

- Usage Image:

Linear Actuators with Handwheel

Relying on its technical strength and experience, Daniyal Para Development Company has the possibility to produce according to your request.

Designed for use in natural gas service

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Designed for use in natural gas service

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Designed for use in natural gas service

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Designed for use in natural gas service

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Technical Specifications

Design and production in pressure classes 150, 300 and 600

Design and production in pressure classes 150, 300 and 600

Design and production in pressure classes 150, 300 and 600

Design and production in pressure classes 150, 300 and 600

Gas pressure reduction stations

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Gas pressure reduction stations

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Gas pressure reduction stations

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Gas pressure reduction stations

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.