Pilot Operated Safety Relief Valve

Pilot Operated Safety Relief Valve

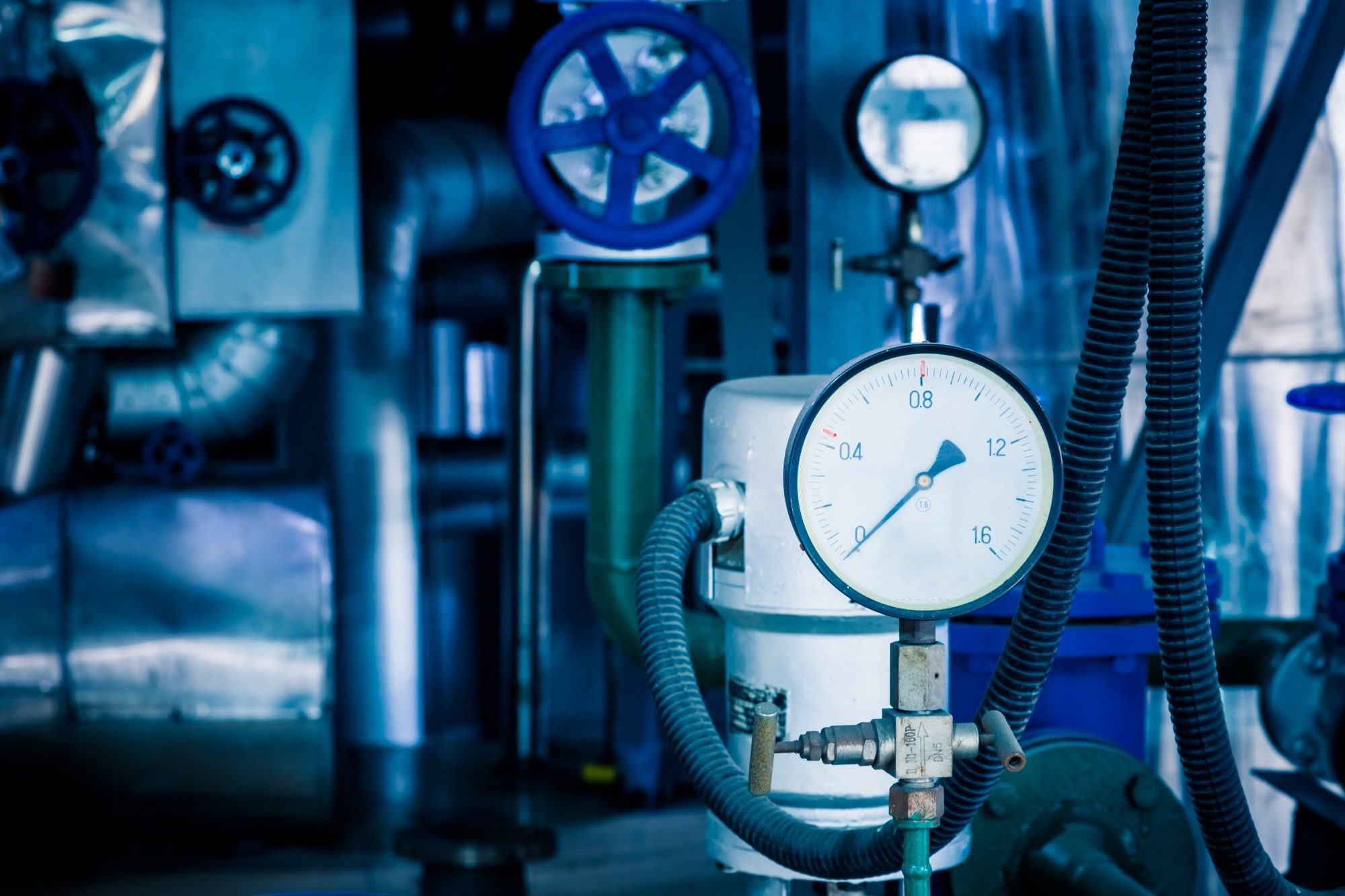

- Picture:

- Checkbox: Yes

- Feature Title: Can be used in natural gas, nitrogen, air and etc Services

- Feature Description: Designed with advanced engineering and high-quality materials, this Safety Relief Valve is suitable for a wide range of gaseous fluids including nitrogen, air, and many others. This versatility offers you greater flexibility and eliminates the need for multiple valves for different fluids.

- Feature Title: Compliant with IGS, IPS and API 526 standard requirements

- Feature Description: Our Pilot Operated Safety Relief Valve fully complies with the highest global standards including IGS, IPS, and API 526. These standards set rigorous requirements for the design, manufacturing, and testing of safety valves to prevent potential accidents and damage.

- Feature Title: Use of stainless steel nozzles

- Feature Description: Stainless steel, renowned for its corrosion resistance and compatibility with a wide range of chemicals, is exceptionally well-suited for corrosive environments. These properties significantly enhance the valve’s durability and lifespan, making it an ideal choice for industrial applications.

- Feature Title: Ability to design and manufacture as SEMI-NOZZLE and FULL-NOZZLE

- Feature Description: Selecting the appropriate nozzle type allows you to tailor the valve to your specific system operating conditions, maximizing its efficiency, reducing initial and maintenance costs, and extending the valve’s service life.

- Feature Title: Full steel pilots to reduce the risk of corrosion

- Feature Description: The high corrosion resistance of stainless steel significantly increases the service life of the pilot and consequently the safety valve. Additionally, all-stainless steel pilots, due to their precise and uniform structure, offer highly accurate and sensitive performance. This feature enables the safety valve to respond to pressure increases in the shortest possible time, preventing accidents.

- Picture:

- Checkbox: Yes

Warning: foreach() argument must be of type array|object, string given in /home/danielco/domains/danielco.ir/public_html/wp-content/plugins/meta-box-aio/vendor/meta-box/meta-box-group/group-field.php on line 453

- Input size from 1 to 8 inches

- Orifice size from 14 to 160 mm in diameter

- Working pressure from 2 to 2000 PSI

- Temperature range -50 to +200 degrees

- Body material SA216 WCB, SA351 CF8M and...

- Standard flanges according to ASME B16.5

- Picture:

- Checkbox: Yes

- Usage Title: gas pressure reduction stations

- Usage Description: In gas pressure reduction stations, these valves play a crucial role in ensuring safety and preventing potential accidents. In case of system disturbances and sudden increases in gas pressure, the safety valve automatically opens to release excess pressure. This prevents damage to equipment such as regulators, meters, and other components, as well as explosions of equipment and pipelines.

- Usage Image:

- Usage Title: Oil and Gas industries

- Usage Description: The oil and gas industry is a hazardous environment characterized by high pressures and temperatures. Any sudden increase in pressure within systems in these industries can lead to explosions, fires, and irreparable damage. Pilot Operated safety Relief valves, as a critical component of safety systems, play a pivotal role in protecting equipment and facilities in these industries.

- Usage Image:

- Usage Title: petrochemical and refineries

- Usage Description: Pilot Operated safety Relief valves are among the most critical safety devices in the petrochemical industry. These valves serve as the last line of defense against excessive pressure buildup in process systems, preventing catastrophic events such as explosions.

- Usage Image:

- Usage Title: Steel industries

- Usage Description: Pilot Operated safety Relief valves are used in the steel industry to prevent excessive pressure buildup in hydraulic systems (pumps, cylinders, and other components), pneumatic systems, pressure vessels, and to protect boilers from explosions.

- Usage Image:

- Usage Title: boilers

- Usage Description: The primary function of these valves is to protect boilers from excessive pressure. If the steam pressure inside the boiler exceeds the allowable limit, the safety valve automatically opens and releases excess steam to prevent boiler explosion

- Usage Image:

Pilot Operated Safety Relief Valve

Relying on its technical strength and experience, Daniyal Para Development Company has the possibility to produce according to your request.

Designed for use in natural gas service

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Designed for use in natural gas service

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Designed for use in natural gas service

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Designed for use in natural gas service

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Technical Specifications

Design and production in pressure classes 150, 300 and 600

Design and production in pressure classes 150, 300 and 600

Design and production in pressure classes 150, 300 and 600

Design and production in pressure classes 150, 300 and 600

Gas pressure reduction stations

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Gas pressure reduction stations

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Gas pressure reduction stations

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.

Gas pressure reduction stations

To change this text, click on the edit button. Lorem Epsom is a mock text with an incomprehensible simplicity produced by the printing industry and used by graphic designers.